Common Terms and Basic Information about Air–Conditioning and Refrigeration Systems.

1. Psychrometry

It is a Greek word study of Air and water vapor mixture (moist air)

2.Properties of Air

1 . Dry Bulb Temperature ( DBT) ( Sensible heat)

2. Wet Bulb Temperature ( WBT)

3. Dew Point Temp ( DPT)

4. Humidity Ratio ( Sp. Humidity for Latent Heat)

5. Relative Humidity ( R.H) for Human Comfort

6. Saturated Air

7. Enthalpy of Air

3.Dry Bulb Temperature

It is same as the room temperature or normal temperature of Air. But it will measure the sensible heat of Air.

4.Wet Bulb Temperature

First measure the dry bulb temperature of the room( Normal temp of air) using a thermometer. Then take a wet cloath, dip with water and tie on thermometer, The cloth will become dry .This temp when measured is called wet bulb temperature ( less than dry bulb temp) say 24 degree c.

Wet bulb temp. is always less than dry bulb temp.

But if We find both temp, (dbt.&.wbt),We can find out other properties of air from psychrometric chart.

5.DPT (dew point temp.)

It is the temperature at which condenser starts working. Summer season is more humid than winter season.

6. Design Conditions :

Summer:

Temperature: 24 degree C (76 F)

R.H – 30 to 60 percent

Winter:

Temperature: 22 degree C (72 F)

R.H – 30 to 60 percent

Coil Surface Temp – 53 F

In Usual Practice

Design temp. = 76 F or 25 degree C

Relative Humidity = 50 %

Some common Terms Used in HVAC

1 .Heat – A form of Energy which transfers due to temperature difference SI Units – KJ, Kcal, B.T.U

2 .Temperature – is the intensity of Energy (Units are C,F, and KJ H = m C delta T

1 BTU – Heat Required to raise by 1 degree F of 1 lb water.

3. Conversion of Temperature From Celcius to Farenheit

0 c = 32 f

100 c = 121 f

C = (F-32)/ 180

Also pleases note that, – 40c = -40 f

4. Ton (Capacity) –The cooling effect of uniform melting 1000 kg of ice (1 ton) by extracting heat from a completely closed room in 24 hrs.

5 .Latent heat of ice = 330 kj/kg

1 TR = 210 KJ/minute

1 TR = 3.5 KW – Mechanical kw only not Electrical KW

1 TR = 1.2 Kw to 1.5 Kw Electrical and Varies according to Machines

Kw – Metric System

Ton – English System

6. Enthalpy

Enthalpy is the Heat content of the body.

H = U +PV

U – Internal Energy

7. Sensible Heat

Where temperature changes by adding or extracting Heat energy (No phase change)

8. Latent Heat

Heat added or extracted without changing the temperature (Constant temp), with a phase change.

Heat gained through ventilation – Sensible + Latent.

9. Pressure (An important parameter in HVAC)

Force per unit area.

Units PSI – Pound per square inch.

Humidity

Moisture In Air.

Humidity Ratio

Moisture per kg of Air ( Sp.Humidity ) used to find the Latent Heat ,It is measured grams/kg.

Relative Humidity

Ratio of Actual Water Vapour Pressure in air ( Standard is 50 %) to the vapour pressure of Air ,when the air is saturated at the exiting dry bulb temp.

Enthalpy

Heat content of Air ( Sum of Enthalpy of Dry Air + Enthalpy of Water vapour in Air).

10. Laws of Thermodynamics

1. Zeroth Law

If two bodies attain thermal equilibrium with a third body all the 3 bodies will be in thermal equilibrium with each other.

First Law of Thermodynamics

Heat and Work are mutually interconvertible.

Second Law of Thermodynamics

Kelvin Planks Statement .

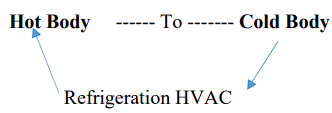

Clausius Statement – It is impossible to transfer heat from high temp to low temp.So the refrigeration system ( Vapour compression System )

Second Body is Important for HVAC

Modes of Heat Transfer

Conduction – Heat Transfer without any solid physical movement (But molecular movement happens)

Convection – Heat transfer due to movement of molecules in Fluids

Radiation – Radiation can transfer heat in vacuum (No medium is required),Heat transfer due to electromagnetic rays.

So Conduction, Convection requires medium, Radiation does not require any medium.

Refrigerant and different types of refrigerants

Refrigerant is the Heat carrying medium Through the Cycle

7. Unit Conversions :

The common conversions used in HVAC Services are:

Electric Power

1 HP = 0.75 KW

Cooling Load

1 KW = 3415 Btu/Hr

1 RT = 3.517 KW

1 MBH = 1000 Btu/Hr

1 MBH = 0.29 Kw.

RT – Refrigeration Tonnage

Pressure

1 Bar = 10 5 Pa

1 Bar = 14.5 Psi

1 Bar = 10 m.w.g

1 Bar = 750 mm of Hg

1 in w.g = 249.09 Pa

Area

1 m2 = 10.76 ft2

Velocity/Speed

1 m/s = 197 fpm

1 fpm = 1 cfm/ft2

Mass

1 kg = 35.27 oz

1 kg = 2.2 lb

1 ton = 1000 kg

Flow

1 l/s = 2.12 cfm

1 l/s = 15.85 US gpm

1 l/s = 3.6 m3/hr

Energy

1 Btu = 1055 J

Temperature

0 C = 0 +273.15

0 F = (0 CX1.8) + 32

Volume

1 m3 = 1000 l

1 m3 = 35.28 ft3

1 Us gallons = 3.785 L

1 UK gal = 4.55L

Length

1 m = 3.25 ft

1 ft = 12 inch = 0.305 m

1 inch = 2.54 cm

1 inch = 25.4 mm

8.Human Comfort :

It is the Satisfaction of the Mind in Existing Thermal Conditions Ashare Standard-55 is the reference standard for Human Comfort. Last updation came on 2020. Method of compliance – Occupant Survey and Physical measurements. We can plot this Comfort zone in Psychrometric chart. Psychrometric chart shows Temperature vs Humidity and can be used to express human thermal comfort.

9.Types of Refrigerants

CFC – Chloro Fluro Carbon ( Used 20 yrs back ) Eg : R 12

HCFC – Hydro Chloro Fluro Carbons Eg : R22

HFC – Hydro Fluro Carbon Eg : R134 A,R 410 A

Zeotropic and Azeotropic Refrigerants

Zeotropic refrigerants expresses temp glide, while azeotropes don’t show glide

10. Tonnage (Ton)

1 TR = 210 KJ/min

1 TR = 3.5 KW ( Mechanical )

1 TR = 12,000BTU/Hr

1 TR = 400 cfm

1 TR = 3.4 GPM (US GPM)( Used in chilled water piping )

= 3000 K cal/Hr

1 Ton = 2.4 gpm ( When ![]() T = 10degree F )

T = 10degree F )

1 Us gpm =3.74 litre

11. Thumb Rule for Tonnage

1 TR = 100 Sq. feet Area (Height 3m)

(Condition is that the room is exposed to two sides)

1 TR = 130 Sq feet

(Condition is that the room is exposed to only one side). Also for no exposed

1 TR = 300 Sq feet (Condition is that the Building is green.

11 .A Drainage Rate of Air Conditioning ( WindowAC)

1 Ton = 1.2 Liters/hr

12. Normal range of Air cooled and water cooled chillers

Air cooled – 15 tr to 3500 tr

Water cooled chiller – up to 6500 tr

13. Refrigerant Piping

Pipes are used to transfer fluids. The copper pipes are used in refrigerant cycles. Both hard and soft copper pipes are used in refrigeration cycles.

Up to 2TR.We use Soft Copper, above 2 TR We use Hard Copper.

Length of Copper Pipe – Normal manufacturer supplies 10 ft copper pipe along with the machine. More than 10 feet, additional refrigerant is needed.

14. Temperature Glide

With single components or azeotropic mixtures the temperature difference from beginning to the end of change from liquid to vapor is Zero. ie ; there is no temperature glide.

When a non-azeotropic mixture boils, there is a rise in temperature of between the bubble point and the dew point, and this change in temperature is called ,Temperature Glide.

Using counter flow heat exchangers can mitigate some of the effects caused due to temp. glide.

15, Ducting

Ducting work is provided in Air Conditioning system for Air Distribution via. Air Terminals.

16. Aspect Ratio

Aspect ratio in ducting = Duct Width/ Duct Height. It should not be more than 4:1

17.Air Velocity In Ducting

Equal Friction Method

In equal friction, We assume that friction is constant every where in ducting.

0.08” Water / 100 ft of ducting to 1” Water/ 100 ft of ducting is taken as a standard for ducting Design.

For Low and Medium Velocity Ducts

Main Duct = 1000 to 1200 fpm

Branch Duct = 750 to 1000 fpm

Supply and Return Grills = 400 to 500 fpm

Nomally return grill velocity to be kept more than the supply grill velocity.

Velocity Reduction Method

Main Duct = 1200 to 1500 fpm

Branch Duct = 750 to 900 fpm

Supply and Return Grills = 300 to 500 fpm

Plennum Box = 500 fpm

Nomally return grill velocity to be kept more than the supply grill velocity

18. Pressure Classification Of HVAC Ducting

Low Pressure Class (Class A)

Static Pressure Limit + ve 500 pa

-ve 500 pa

Max Velocity – 1969 fpm ( 10m/s)

Medium Pressure Class ( Class B)

Static Pressure Limit + ve 1000 pa

-ve 750 pa

Max Velocity – 3937 fpm (20m/s)

High Pressure Class ( Class C)

Static Pressure Limit + ve 2000 pa

-ve 750 pa

Max Velocity – 7874 fpm (40m/s)

19. Pressure classification of Refrigerants

Refrigerants re classified as Low, Medium and High

High Pressure Refrigerants

R-22

R 407 C

R 410 a

R 502

Medium Pressure Refrigerants

R12

R 134 a

R 500

Low Pressure Refrigerants

R 11

R 123

R 113

20.Hvac Ducting Gauges

Commonly used gauges are 22 and 24 in G.I ducting

22 gauge is used for velocity up to 1200 fpm ( 1 mm thickness)

24 gauge is used for velocity up to 750 fpm ( 0.8 mm thickness)

21.Chilled Water Piping

Chilled water piping is provided for distribution of Cold water to different equipment such as AHU,FCU From Chiller Plant in HVAC Systems.

Gpm Gallons per minute) = Tonnage in TR X 24/ ( Delta T).

Piping Design Flowrate as per the location of the Building

Roof Chilled water Piping = 15 Fps ( Max)

= 0 Fps ( Min.)

Riser Velocity = 7 fps to 10 fps

= 9 fps ( Normal Design Parameter)

Floor Piping = 5 fps to 7 fps

Can be taken less than 5 fps But not less than 1.5 fps